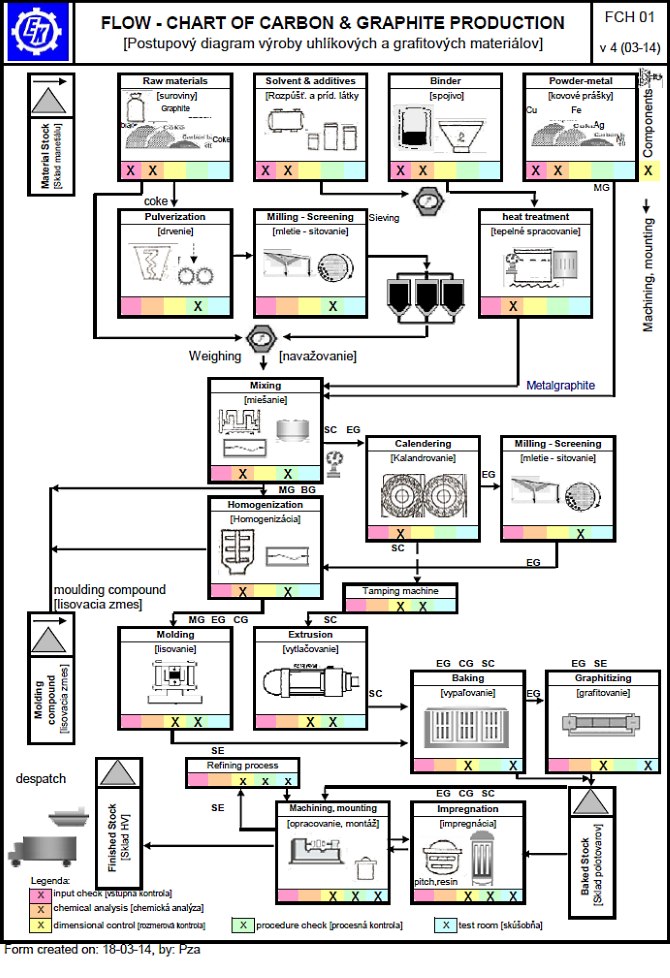

ELEKTROKARBON has integrated production cycle - from half-products till final products.

High quality of products is ensured by progressive production technology and highly qualified personnel.

The products are produced according to international standards - ISO in areas of quality and environment.

The production of carbon materials and products is realized in three plants of the production facility in Topoľčany - first plan produces from half-products from raw materials, second plant produces carbon brushes and third plant produces carbon strips and machined carbon products.

Existing capacity of the production plants enables the Company to produce broad range of products and react flexibly to customers demands regarding different sizes of production batches - small amounts of high number of different products, as well as high amounts of fewer products.

The following technologies are used for production of carbon products:

|

|

1.7.1. - Flow chart EKT v4-14 -Final.pdf |

|

Contact us

ELEKTROKARBON a.s.

Tel.: +421 38 535 41 11 |

|